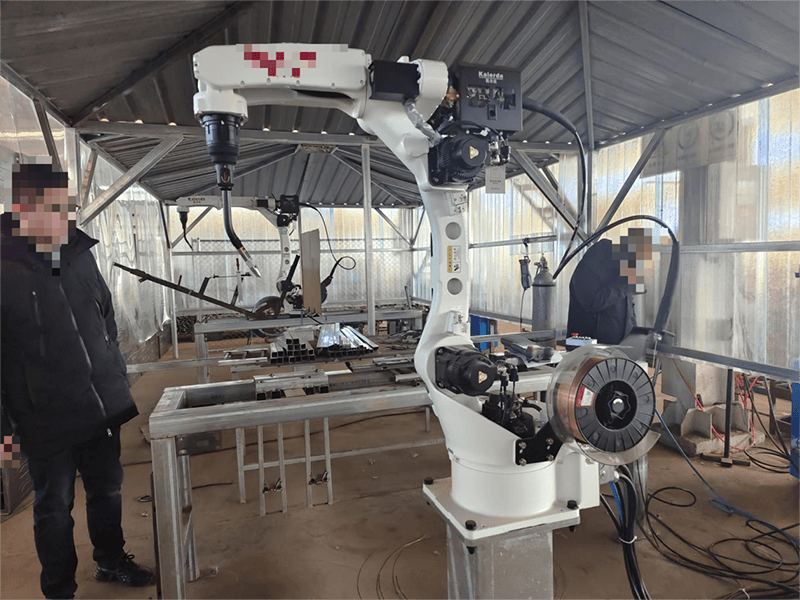

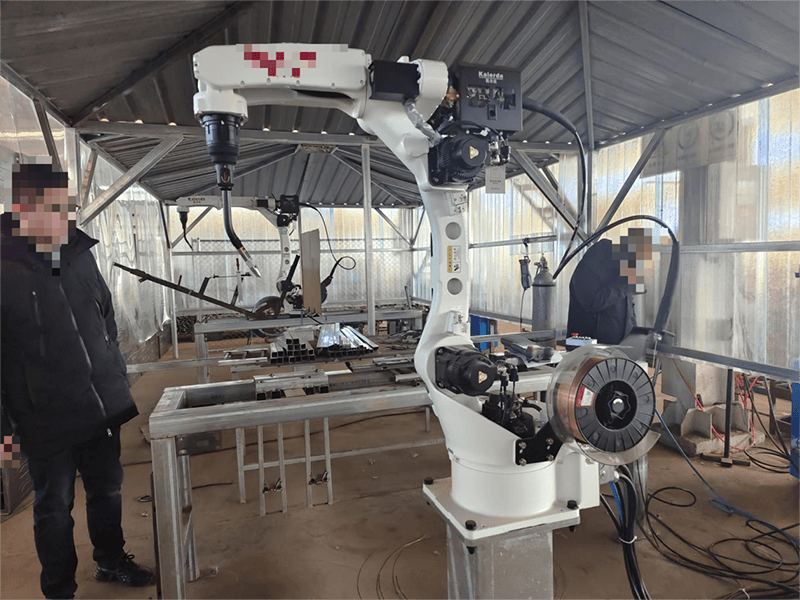

Cov neeg hlau zoo li no tsis muaj qhov yuam kev ntawm kev sib dhos ua haujlwm, thermal deformation nyob rau hauv cov txheej txheem vuam ib puag ncig hloov, nrog rau cov khoom ua haujlwm hloov yuav tsum muaj peev xwm, yog li ntawd, tsim ib lub cim tshiab ntawm muaj ntau yam kev paub txog kev ua haujlwm, tuaj yeem tsim txoj hauv kev, welding lub sij hawm tus cwj pwm thiab vuam tsis muaj kev txawj ntse neeg hlau yuav dhau los ua lub ntsiab txoj kev loj hlob.

Cov neeg hlau zoo li no tsis muaj qhov yuam kev ntawm kev sib dhos ua haujlwm, thermal deformation nyob rau hauv cov txheej txheem vuam ib puag ncig hloov, nrog rau cov khoom ua haujlwm hloov yuav tsum muaj peev xwm, yog li ntawd, tsim ib lub cim tshiab ntawm muaj ntau yam kev paub txog kev ua haujlwm, tuaj yeem tsim txoj hauv kev, welding lub sij hawm tus cwj pwm thiab vuam tsis muaj kev txawj ntse neeg hlau yuav dhau los ua lub ntsiab txoj kev loj hlob.

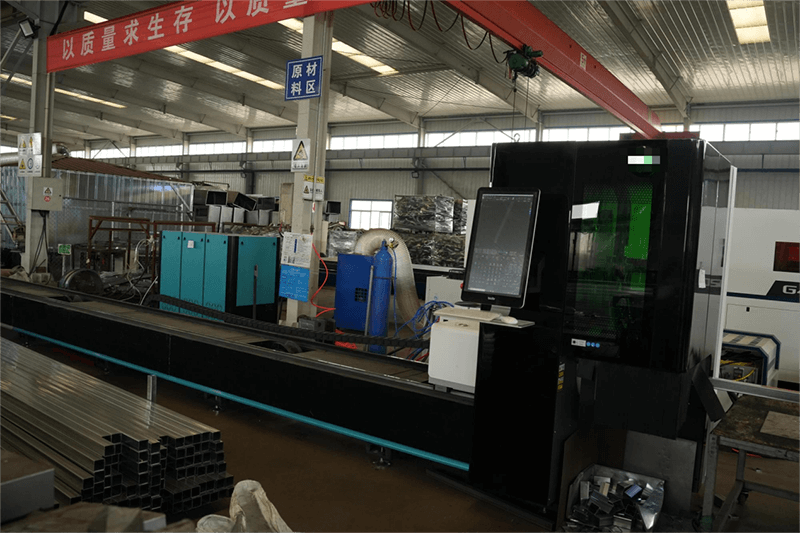

Kev tsim cov ntaub ntawv tshiab yuav raug tsim los ntawm kev ua haujlwm siab, kev ua haujlwm siab (nrog rau kev sib txuas zoo) thiab cov txiaj ntsig ib puag ncig.Vuam yuav txhim kho cov txheej txheem vuam zoo dua, tsim kom muaj kev sib txuas zoo dua qub thiab txhim kho cov cuab yeej tswj kev sib raug zoo, txhim kho qib ntawm automation thiab nthuav dav daim ntawv thov ntawm cov neeg hlau: txo cov seem seem thiab kho tus nqi, txo cov nqi vuam, txhim kho cov khoom. efficiency (xws li: txo, tom qab preheating, tshav kub, tsis txhob welding overheating, thiab lwm yam), tshem tawm lub tswvyim ntawm "welding yog ib tug raug txheej txheem teeb meem".

Post lub sij hawm: Jun-18-2024